PLUG-IN Project

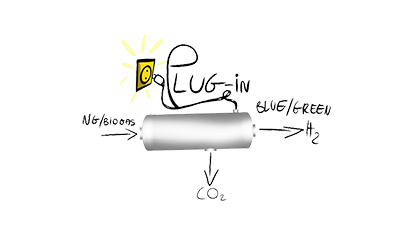

The Paris Agreement of 2015 set a global target to limit warming to 2°C above pre-industrial levels, requiring a reduction in greenhouse gas emissions by 80-95% by 2050. In response, hydrogen has become a key focus, particularly within initiatives like the European Green Deal. The PLUG-IN project explores the potential of electrified Steam Reforming (SR) of Natural Gas and Biogas to produce low-carbon hydrogen (blue/green H2) for distributed applications.

The project proposes using renewable electricity, supplied by microwave or resistive-/inductive-joule heating, to heat up steam reforming (SR) tubular reactors designed for the production and simultaneous separation of high-purity H2 in a single compact process unit. In line with the emerging industrial electrification strategy, the project will address the main critical issue of the SR process, represented by the enormous thermal duty required for the feed heating and for the reaction endothermicity, by replacing equipment, such as boilers or furnaces, that run on conventional fuels.

To this purpose, PLUG-IN will explore original synergistic intensification routes to develop a new generation of electrified multifunctional SR reactors characterized by the integration of conductive structured catalysts (e.g., coated or packed foams) with H2 selective membranes or CO2 sorbents, based on the following rationale: 1) Conductive structured catalysts susceptible to microwave- or joule-heating enable direct energy supply to the catalyst, removing the rate-limiting heat transfer of conventional reformers, granting a more uniform temperature distribution and a higher catalyst effectiveness; 2) The adoption of either H2 perm-selective membranes or CO2 sorbents in the reformer removes chemical equilibrium limitations and allows to carry out both the reforming reaction and the H2 separation/purification stages simultaneously in one device, enabling both recovery of a high-purity H2 stream and effective CO2 sequestration.

The PLUG-IN innovation will enable a dramatic reduction of the number of process units and of the SR volume, as well as faster transients and the adoption of cheaper materials, thus making low-carbon hydrogen more sustainable in terms of costs and footprint and paving the way to the urgently needed Power-to-Hydrogen technologies. To achieve its goals, PLUG-IN will combine model-based design with lab- and bench-scale experimentation to identify the optimal multifunctional reactor design. The ultimate project target is the comparative evaluation of the investigated process configurations from the energetic, economic and environmental standpoints.